In the industrial realm, precision is paramount. The accuracy of measurements can make or break manufacturing processes, directly influencing product quality and consistency. In sectors like aerospace, automotive, electronics, and metalworking, even minute discrepancies can have significant repercussions ranging from safety concerns to functional failures. This underscores why precise measuring tools are indispensable in these settings.

Traditional measuring instruments such as rulers and analog calipers have been employed for ages. However, they often fall short when extremely high precision is required. Enter digital vernier calipers – a modern tool that offers unparalleled accuracy and ease of use. Unlike their analog counterparts, digital vernier calipers feature an electronic display, which makes reading measurements straightforward and error-free.

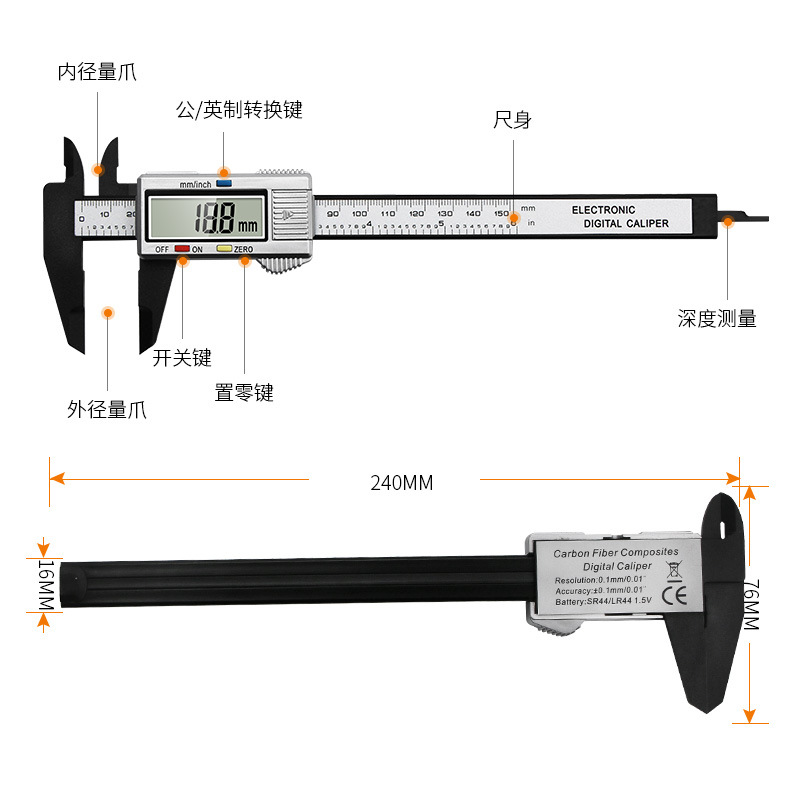

Digital vernier calipers comprise several key components: a main scale, a sliding vernier scale (or jaw), an electronic display, and depth-measuring probes. One of their standout advantages is the ability to quickly switch between different units (millimeters and inches), making them versatile for various international applications. Additionally, the zero-setting function allows measurements relative to any point, adding another layer of convenience.

The benefits of using digital over analog calipers extend beyond merely improved readability. Digital calipers offer higher precision levels due to reduced chances of human error, thanks to clear numerical displays. They also provide more consistent readings across multiple uses and users, which is essential for data integrity in quality control workflows.

The versatility of digital vernier calipers makes them invaluable in multiple industrial sectors. For instance, in the automotive industry, these calipers ensure parts fit together perfectly, maintaining performance and reliability. Measurements need to be exact to prevent assembly issues or performance drops in finished vehicles. In the aerospace sector, where every component must adhere to stringent standards for flight safety, digital calipers offer the required critical measurements with utmost accuracy.

The electronics industry deals with small, intricate components where traditional tools can't always deliver the necessary precision. Here, digital vernier calipers excel by allowing engineers and technicians to measure small items accurately without obscuring readouts. Metalworking relies heavily on precise machining and fabrication, and digital calipers help achieve tight tolerances, improving overall product quality and reducing material waste.

For accurate measurement using digital vernier calipers, follow a step-by-step approach. Firstly, ensure the caliper is clean and reset it to zero before each use. Place the jaws around the object being measured and gently close them until a snug fit is achieved. Read the displayed value straight off the screen. Mistakes such as applying too much force or neglecting calibration can lead to inaccurate results.

Proper maintenance includes regular cleaning and periodic recalibration. To avoid common pitfalls, always store the caliper in its protective case and remove the battery if it's not going to be used for an extended period to prevent leakage.

An exciting development comes from integrating digital vernier calipers with other technologies. When used alongside CAD software, these calipers facilitate seamless transition from design to production, ensuring that prototypes match their digital blueprints precisely. Modern models support Bluetooth and USB connectivity, enabling easy data transfer to computers and other devices, thus digitizing records and fostering a paperless environment.

Automation is revolutionizing how measurements are handled in industrial processes. Digital calipers can be integrated into automated workstations, collecting data effortlessly while linked to broader factory systems for real-time monitoring and adjustments.

Industries worldwide have already reaped substantial benefits from implementing digital vernier calipers. Take, for example, an automotive firm that drastically reduced part rejection rates due to enhanced measurement accuracy. Or consider an electronics company that sped up its production line by cutting the time spent manually logging measurements. These successes highlight both improved efficiency and lifted standards of product quality.

A practical question arises about cost-effectiveness. Investing in digital vernier calipers initially might seem steep compared to analog tools. However, the long-term benefits far outweigh the costs. Precise measurements reduce material wastage, lower rejection rates, and improve process efficiencies, cumulatively leading to significant savings over time. Moreover, producing consistently high-quality products enhances brand reputation and customer trust.

Proper training ensures operators harness the full potential of digital vernier calipers. Training programs and certification courses are available, offering comprehensive guides on usage, maintenance, and integration techniques. Regular skill updates keep professionals abreast of technological advancements, further leveraging the capabilities of these instruments.

The future promises continued evolution in measurement technology. Emerging innovations include smarter calipers equipped with predictive maintenance features linked to IoT systems, providing diagnostics and alerts before malfunctions occur. Such advances will undoubtedly push the boundaries of what’s achievable, driving ongoing improvements in precision measurement and operational efficiency.

The Electronic Digital Display Vernier Caliper 0-150mm available at Yiwu Mall epitomizes these advancements. Featuring high-strength plastic construction for durability and capable of measuring both inside and outside diameters with precision, this tool showcases the best of modern measurement technology. By adopting tools like this, industries set themselves on a path toward superior performance and meticulous craftsmanship.